Collaborative Robots for Optical Component Manufacturing

Home >

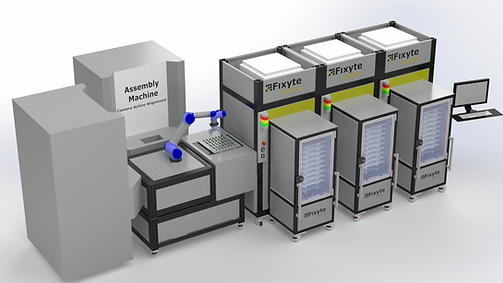

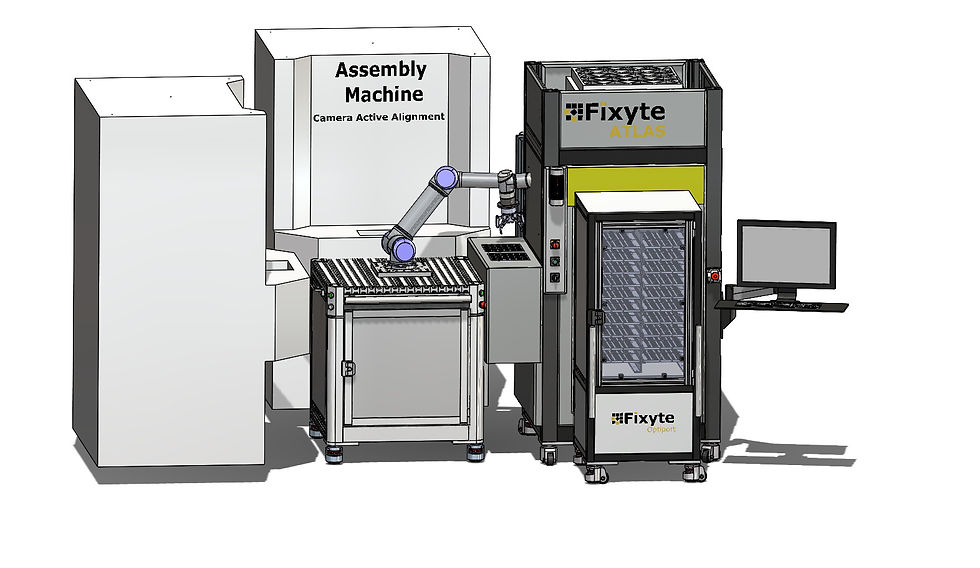

Advanced Collaborative Robot Systems for Precision Optical Assembly and Handling

Professional collaborative robot (cobot) systems designed for optical component manufacturing. Our precision automation solutions enable safe human-robot collaboration for assembly, handling, and quality control in optical manufacturing applications.

Precision Cobot Systems Explained

Collaborative robots (cobots) provide safe, intelligent automation that works alongside human operators in optical component manufacturing. Our optical manufacturing cobots are specifically designed for the precision, safety, and flexibility required in delicate optical component handling and assembly applications.

This automated work cells focus on a collaborative robotic arm that interacts with all workflow machines integrated into the AMHS. This collaborative robot is perfect transferring optical components between the AMHS system and the assembly/processing machine with precision and efficiency. The robotic end effectors are designed for dual pick-and-place, allowing for the handling of multiple components and minimizing the robotic arm's travel time.

Cobot System Advantages:

-

Safe human collaboration with advanced safety monitoring

-

Precision optical handling for delicate component assembly

-

Flexible automation adapting to changing manufacturing requirements

-

Enhanced productivity combining human intelligence with robot precision

Cobot Integration and Customization

Manufacturing Integration Services:

-

Consistent precision maintaining quality standards across shifts

-

Reduced operator fatigue automating repetitive precision tasks

-

Enhanced throughput optimizing human-robot task allocation

-

Flexible operation adapting to changing production requirements

Technical Development Process:

-

Standardized processes ensuring consistent handling techniques

-

Reduced variability minimizing human error in precision tasks

-

Enhanced inspection automated quality control with human oversight

-

Continuous improvement data collection for process optimization

Ready to Partner?

Let’s talk about the challenges you’re up against and how Fixyte can help.